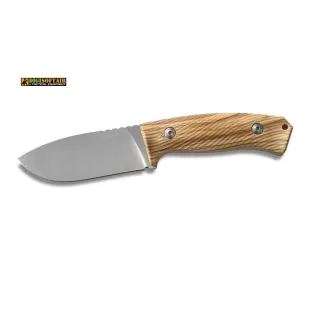

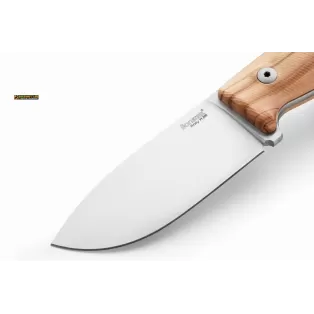

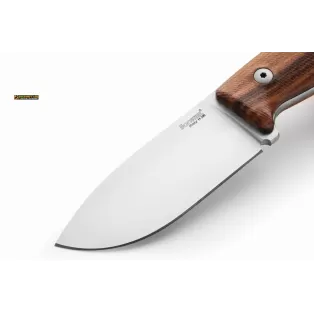

List of products by brand Lionsteel

lionsteel, one of the best Italian cutlery companies ever existed, technology and technique are always at the forefront, winners of various awards and a story to be discovered, their blades are not only of excellent quality but are perfectly assembled, nothing is left to the case, every screw, pin and any detail inserted has been researched, designed and produced by them for a specific purpose

Morelionsteel, one of the best Italian cutlery companies ever existed, technology and technique are always at the forefront, winners of various awards and a story to be discovered, their blades are not only of excellent quality but are perfectly assembled, nothing is left to the case, every screw, pin and any detail inserted has been researched, designed and produced by them for a specific purpose

What a thrill to know one of your own creations is "best knife of the year" at the Blade Show in Atlanta. It is the sixth award, since 2012. It is quite impressive to have started from little Maniago, from our grumpy foothills, and now be here, triumphant, in the largest cutlery fair in the world, in the city of Coca Cola, with the airport holds the planetary passenger record. Little David from Friuli continues to beat the Goliaths of American industry. This is the third “Overall Knife of the Year”, after the 2014 one won by TiDust and the 2015 one signed by T.R.E. Titanium. Hat-trick, to which is added an even more prestigious achievement: the "Manufacturing Quality Award" which in 2014 consecrated LionSteel as the best company, displacing the usual Yankees from the highest podium after an immemorial time. To find a football metaphor, it's like winning a final of the World Cup in Rio de Janeiro, against the cariocas, with an amateur team. Too bad there is nothing amateurish about the industrial performance of LionSteel, except for one ingredient that has remained the same for almost sixty years, since Gino Pauletta opened his existential account with knives. An increasingly rare and precious spice: passion.

Today, in Atlanta, his son Gianni is collecting the laurels. Yes, because Gino is one of those stubborn craftsmen who doesn't give up the workshop, but willingly leaves the reins. He knows that the same incandescent dream can take on new technologies and new materials, take unforeseen paths and young people must follow them, less intoxicated by nostalgia and with more energy to get involved. At the stroke of the new century, or rather the new millennium, Gino thus passed the baton of the enterprise to his sons: Daniele, Gianni, Massimo.

The factory, however, never left it, let alone. He is always there, with his master's touch, with his desire to create toys that often become jewels and sometimes inspire products. Gino is the magician who thinks with his hands and, when he thinks, his clear eyes laugh, and it almost seems that the object reflected in the iris precedes the magical creation by a few moments. Every gesture has the right weight, the right direction. It began as a boy, Gino, on 1 January 1957, at FARM, Maniago Reclame Articles Factory. To emancipate himself economically and feed his insatiable passion for him, he didn't hesitate for a moment to add to the stamped hours those of after dinner, Saturdays and Sundays, on behalf of third parties. That's how he went in those days: even fifteen hours a day, because the wages of a worker weren't enough, especially if you wanted to start a family.

Then, in 1969, the time came to detach, like the LEM, which that same year would undock from Apollo 11, to reach the Moon. Gino could not have known where his moon would be, but he had still wanted to become an artisan entrepreneur and continue alone along his path, with the enthusiasm of someone who feels they have America within them. Inside him roared that lion that his stonemason ancestors had carved with the stone of Monte Jouf and in his courtyard he eyed the children with a wickedness that made you shiver. That indomitable beast would remain imprinted on him forever, it would become his trademark, for its primitive strength and, even more, for what it meant: his being an imagined form and extracted from the raw material. That shape that only he sees inside the raw metal, that thread that he caresses with his gaze, that imperceptible curve that only to him seems valley and mountain and that needs to be filed and filed, to reach the perfect slope, because the side-by-side blades of the multipurpose knife skim to the tenth of a millimeter, without touching, to fall into their seat with that "click", which delights the finest ears. What music!

Who cares, then, if they are not always knives. What matters is making, taming the lion, shaping the metal: in 1969, to inaugurate the company's activity, an order for a hundred can openers for the Farfalli company, which soon became 3000, 3500... Followed by the sharpeners for Coricama , who take the road to Milan, to Rome, to Germany.

It is not yet time for America: at the moment even Italy and Europe can suffice.

It's a warm winter day in 1978. In Friuli the earthquake has still left many open wounds, but we mustn't complain: the economy has restarted at full speed, there is no shortage of orders, we can afford a few days of leisure.

Gino, with his wife Cesarina, is visiting relatives in Milan. They stroll in the Gallery, under those glass vaults ribbed with metal. Gorgeous. Yes, he can understand it. The eye falls out – who knows why? – on the window of a gift shop. Everything around disappears. Like a mirage in the desert, only that switchblade, made in the USA, shines. It is a showever seen: you have to enter, buy, whatever the cost. Sixty thousand lire. A nice figure. Indeed, a good investment. The marvel, this time, is all concentrated in the handle, built with two materials married in inlay. There is no time to lose. We need to replicate that masterpiece, with an extra touch of innovation, made in Maniago. We need to put Japan and Italy together.

Gino senses two perfect materials to score: brass and olive wood. He is the first to think of this elegant combination. Even the olive tree, alone, would already be a great novelty.

The time has come to industrialize the idea and, as they would say today, to bring together the "rope mates". For the most critical processes, he finds the right person in Malnisio: he can finally start with the first prototypes. Production can finally start.

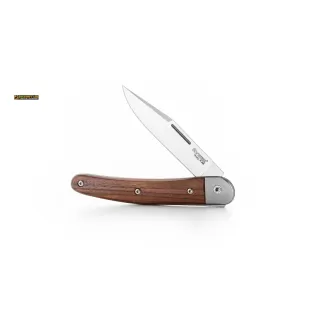

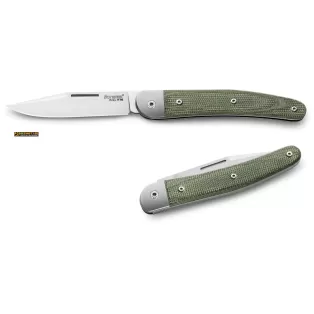

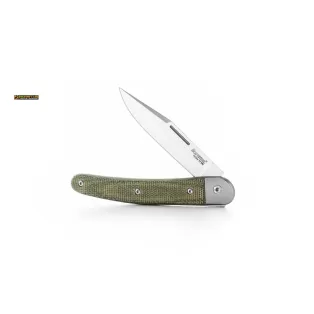

The article 110 was born: the praise was given to him by the market, with a boom in sales between 1979 and 1980.

In this parable there is all the excellence of Gino: the glance, the ability to internalize an innovative idea and make it even newer, the enthusiasm that multiplies forces and unites people, the desire to free oneself from the yoke of "third party" work, to create something of its own, which proudly walks with its head held high, which claims its own exclusivity. “We were able to sell that item 110 for 8,500 lire, the factory price. Not bad for those times. Each piece gave us its beautiful profit. And the company grew with the revenues.” This is what an entrepreneur is. One who knows how to imagine the value of an object that does not exist, of a product that will be, and then persists in creating it, giving it life with his own hands. Gino was like this, ever since he was a boy, when he worked at FARM, ever since that day when he found a nugget on the Colvera, the stream that has fed the mills and grindstones of Maniago for more than a thousand years, that living water that transforms metal. The nugget was cutlery waste. In that raw gift, in that refusal of industrial civilization, Gino had seen the shape of his first knife and sharpener, he had kept it within himself so that it would not run away from him and, with few means and a great deal of good will, he had freed it from its shapeless fate.

When he thinks back to his first youthful venture, he feels even closer to his children, to each of whom he has passed on some piece of his passion. Gianni travels the world chasing (and bringing) novelties and today he is in Atlanta. Daniele and Massimo work alongside him in the workshop and continue to listen to his advice, but luckily they don't always agree with him. He expects, however, that passion has poured from his crucible and now flows into their lives, into their veins, to surprise him every day with new creations that he would not have even been able to imagine. How many materials. How many processes have changed. How the production of blades has speeded up, with 3D design, water jet cutting, laser cutting. And yet, looking at the essence of things, there is no great difference between yesterday and today. The real forge is inside our soul, the bellows is the beating of our heart. High technology, that of him and that of his children, is above all high imagination, a journey of the mind inside the form, anticipating the roughness and resistance of that material that one must know and love, in order to fight it honestly. To finally win the lion.

When he looks at the products of the last decade, it seems impossible to Gino that his boys could have created a monolithic titanium handle, milled from a single piece. Or the light, perforated TiDust one, obtained with the selective fusion technique from titanium powder: the first knife in the world produced with aerospace technologies!

The LEM that detached from Apollo 11 when he set up shop is still en route. He sails beyond the Moon, beyond Jupiter, towards infinity: with the crew of his children, as long as the desire to explore lasts.

Even if as a true Maniago he finds it hard to admit it, Gino is proud of his children.

He is proud that right now Gianni is there, in America, receiving the first prize.

Gino has never been to America.

America came to meet him. That day, in Milan.

”Maniago, handmade stories” - Photo by Ruggero Lorenzi - Tales by Romeo Pignat